Improving on OEM Standards

Quality is why more savvy technicians will choose ARCO parts over OEM parts. With every part that we stock, we look for ways to improve on the standard set by the OEM.

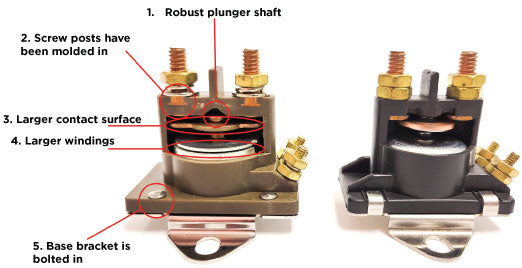

We do stock solenoids that meet the OEM standards, at a fraction of the price. We also stock solenoids that exceed the standards set by the OEM, at a lower price. Below you will see a side-by-side comparison of a standard solenoid and an ARCO heady-duty solenoid that exceeds the OEM standard.

1) The heavy-duty solenoid is built with a robust plunger shaft. The more robust plunger shaft featured in the heady-duty solenoid helps drive the contact plate into the screw contact.

2) In the heavy-duty solenoid, the screw posts have been molded into the body of the solenoid. This is to prevent the post from spinning after regular use. With

standard solenoids, the screw post is simply screwed into the mold. Overtime, it is common for screw posts to spin when tightened at the top, and this will disrupt the connection.

3) The contact surface has been expanded from the standard solenoid. This will provide 100% connectivity to the standard 40% connectivity.

4) Larger windings have been installed into the heavy-duty solenoids, when compared to the standard solenoid. Larger windings will increase the current flow. This assures a more efficient plunger action.

5) On standard solenoids, the base bracket slides and hooks into the base of the solenoid. For the heavy-duty solenoid, the base bracket is bolted in. This provides additional stability.

Learn more about about our high-quality parts here: